What Is Digital Twin Technology and How Does It Work

30 SEPTEMBER

Digital twin technology has gained popularity worldwide. The global digital twin market size was valued at USD 17.73 billion in 2024 and is projected to grow from USD 24.48 billion in 2025 to USD 259.32 billion by 2032, exhibiting a CAGR of 40.1% during the forecast period. North America dominated the digital twin market with a market share of 38.35% in 2024.

Before getting into adoption and digital twin technology use cases, the most basic question is: what is digital twin, and how digital twin works In practical terms, a digital twin is a virtual replica of a physical thing, process, or system that’s synchronised with real-time data streaming from the thing or system it represents, according to its sensors and IoT devices.

Consequently, the mix described here endows businesses with the freedom to do analysis, simulation, and optimisation on another level, not possible with classical simulations.

The concept of the digital twin, which can simulate when equipment might fail or help design safer cars, is moving from the manufacturing world to the mass market.

What is a digital twin?

Digital twins are virtual representations of real-world objects. Think of it as a funhouse mirror that not only looks like the original but also behaves like it, as it inches in the direction of the original image, thanks to a constant freshening from various sensors, historical records, and external data.

Here is a digital twin definition exploration:

- A Physical Object or Process refers to the actual machine, product, or system.

- Data Connectivity is a flow of real-time data from IoT sensors, cloud computing platforms, and analytics tools.

Digital Twin vs. Simulation

There have been simulations for decades, but what was new here was the concept of real-time connectivity. Conventional simulations are based on simplifying assumptions and fixed inputs; in contrast, digital twins reflect reality, adapting dynamically to changes in the physical asset. For example:

- One simulation could be to test how a naval jet engine performs under different conditions.

- A digital twin of the same engine would track it at all times, through a process of continuous monitoring of the asset’s state, predicting when maintenance would be needed, and recommending ways to increase efficiency based on the collected data.

At its heart, digital twin technology isn’t a visualisation tool; in reality, it’s a means of continuous learning, of adaptation, and prediction.

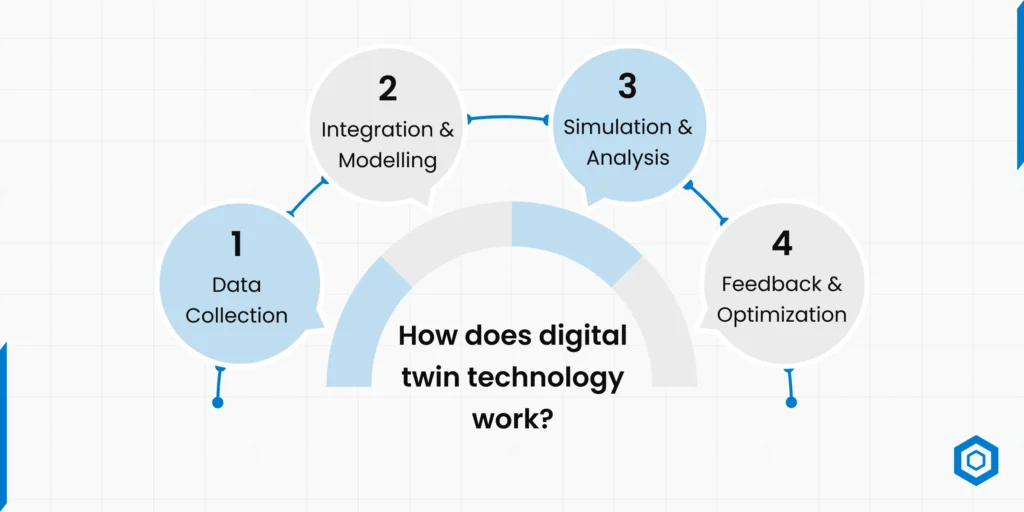

How does digital twin technology work?

It is helpful to divide the process into several steps to comprehend how a Digital twin artificial intelligence operates:

- Data Collection

Sensors, such as those feeding data to IoT devices on assets and connected systems, or even at industrial sites, capture digital twin real-time data from equipment, processes, or environments. From the steady stream of data, the digital twin is scaffolded. The more information provided, the more accurate the virtual copy will be.

- Integration and Modelling

The data is then input into sophisticated modelling software to produce a virtual model of the asset. Because situations change, these dynamic models are constantly updated. The seamless merging of the digital and real worlds is made possible by this catalyst.

- Simulation and Analysis

Once built, the digital twin simulates everything from performance and efficiency to potential hazards. Companies can now review the results, anticipate potential failures, and direct ‘what-if’ scenarios. This type of analysis is on the nose, but it doesn’t disrupt production in real life.

- Feedback and Optimisation

The learned experiences from simulators get re-injected into the physical device to enhance the robustness. Virtual tuning then further improves these for the operations. This cycle is always improving, safer, faster, and more effective.

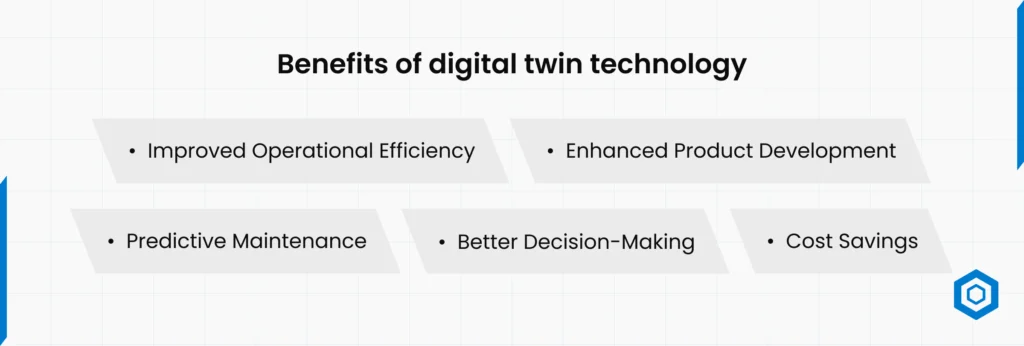

Benefits of Digital Twin Technology

Adopting digital twin solutions provides businesses with an unfair advantage in asset management, performance optimisation, and innovation. But it’s so much more than that, and the real-world benefits are enormous:

- Improved Operational Efficiency

The twins provide an operational view without human assistance throughout the entire period, enabling companies to identify inefficiencies and reduce downtime. “If you simulate things before doing it, you can avoid costly stoppages. As a result, the operations are more efficient and more productive on multiple tasks.

- Enhanced Product Development

Digital twins can also help manufacturers create virtual prototypes, test products, and understand how they function in various scenarios. This speeds up development by reducing prototype back-and-forth. The result is that companies are getting better products to market faster.

- Predictive Maintenance

By tracking the health of their equipment through digital twins, they predict failure. Early diagnosis reduces unscheduled downtime and costly repairs. Equipment lifetime and efficiency are improved by scheduled preventive maintenance.

- Cost Savings

So, digital twins can also help reduce waste here by more efficiently using resources and cutting down on trial and error in operations. Those savings add up for an honest business.

- Better Decision-Making

Offering up-to-date information and simulations, digital twin technology provides leaders with a much deeper understanding of their performance and potential risks. This ability enables more confident, data-driven decision-making across all levels of operation.

Applications of Digital Twin technology in different industries

Digital twin technology applications are vast and expanding. How industries are adopting it:

- Healthcare

Digital twins can enable doctors to trial therapies, predict patient recovery, and iterate care in a safe and efficient way. Hospitals employ them to improve efficiency, reduce errors, and follow patients over time.

- Manufacturing

In the future, applications of digital twinTech can be found in production to become a smart factory with real-time monitoring, predictive maintenance, and production optimisation that minimises downtime and decreases the operational costs.

- Automotive

In the automotive field, digital twins are used for virtual performance simulation for developing cars, battery design optimisation for electric vehicles, and improvement of autonomous driving systems to speed up development and safety verification.

Car makers have better information about how people drive and how their vehicles hold up over time.

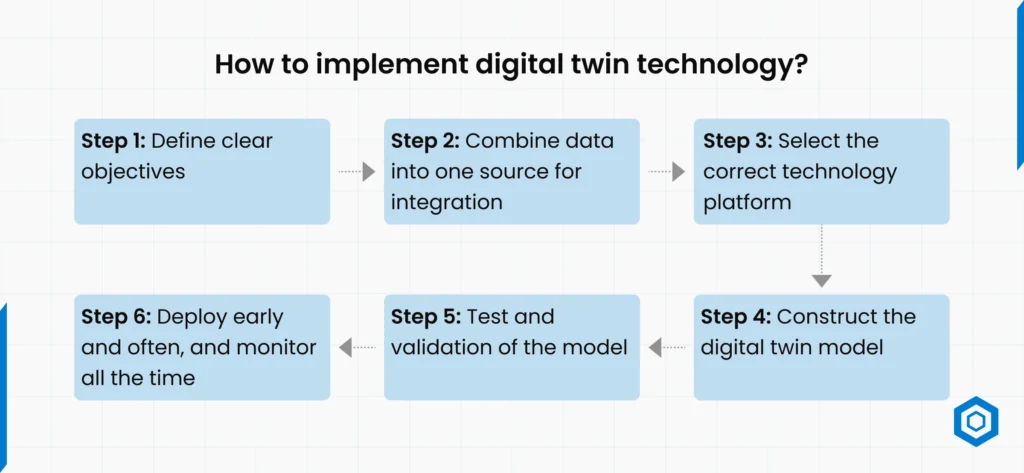

How to Implement Digital Twin Technology?

Understanding the digital twin definition is one thing; putting it into practice is another. For startups and enterprises alike, adopting digital twins requires a clear roadmap:

Step 1: Define Clear Objectives

The first step is to identify what you want to achieve with digital twins, whether it’s improving product design, predicting maintenance needs, or optimising processes. Having clear objectives ensures that the implementation aligns with business goals and delivers measurable outcomes.

Step 2: Combine data into one source for integration

For digital twins to be successful, they must have accurate, real-time data input from systems and devices like IoT, machines, and existing systems. When you combine this data, you need a good foundation to make your virtual models behave just like the real thing. Without good data, the digital twin has no hope.

Step 3: Select the Correct Technology Platform

Scaling, real-time analytics, and system integration all use digital twins. An essential requirement for scaling, real-time analytics, and system integration is the correct digital twin platform.

The platforms need to allow advanced visualisation as well as AI-based predictions and easily offer digital twin IoT integration for better process optimisations.

Step 4: Construct the Digital Twin Model

When the stage has been established, the digital twin model is built by transforming physical objects into their digital representations. Data, 3D modeling, and process simulations are used to precisely represent the system. A well-conceptualized model allows for making well-founded decisions.

Step 5:Test and validation of the model

That digital twin has to be verified and checked to be sure it’s modelled correctly and will deliver the right behaviour as it simulates physical processes before it goes live.

Optimizing the model to prevent errors would be an asset to stakeholders, serving as a means of validation. This phase must be in place before determining if the predictions are plausible and actionable.

Step 6: Deploy early and often, and monitor all the time

The digital twin is included in the product for routine monitoring and operation after validation. Therefore, the maintenance scale must be kept up to date, i.e., the model can be physically mapped. Continual monitoring ensures your tech continues to deliver results, yielding a strong ROI in the long run.

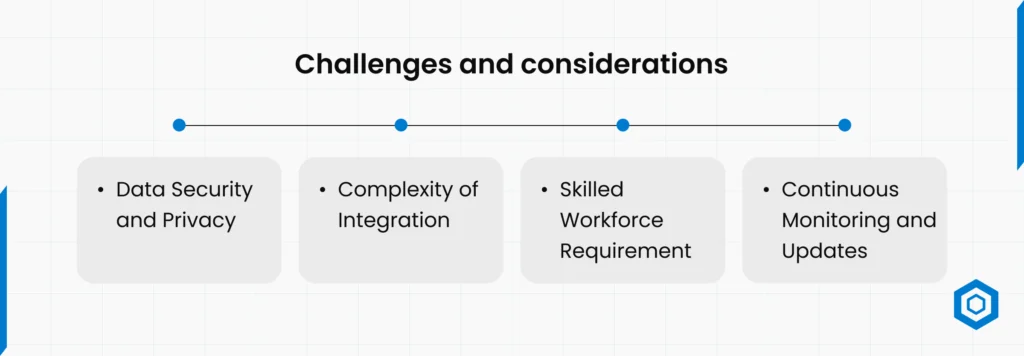

Challenges and Considerations

It is an attractive proposition, but enterprises have to clear some hurdles:

- Data Security and Privacy

Deploying digital twins involves gathering huge volumes of sensitive data from the machines, devices, and end users, a process that comes with profound security implications. Businesses should require encryption, access control, and compliance. Preventing breaches and sustaining confidence requires data privacy.

- Complexity of Integration

We found that the traditional heritage, such as real-time ERP, CRM, and IoT framework, is slow and complex, making it impossible to connect the digital twin to it. Needs another hack or a plug-itable solution in your IT landscape. Some of these might be good for a person’s health overall, but the tangle made them hard to try on, and, meantime, it was going to take planning.

- Skilled Workforce Requirement

To develop and maintain digital twins effectively requires competencies in data analytics, IoT, simulation, and systems integration, all skills that companies require their employees to utilise.

Lack of these skills can impede adoption and reduce effectiveness. On the other hand, constant skill upgrade and training become a necessity to enable smooth deployment.

- Continuous Monitoring and Updates

It is not a single configuration but a system that changes along with the physical asset that it describes, both in time and with new available sources. Constant vigilance, updates, and adjustments are necessary to ensure the model remains valid. Without this, predictions become unreliable, and the technology loses its effectiveness.

The Next Steps for Digital Twin Technology

Going forward, the prospects of digital twin technology remain rosy and not far from developments in AI, IoT, and cloud computing.

- Increased Adoption Across Industries

The concept of a digital twin seems destined to spread from manufacturing and healthcare to retail, construction, and even city planning. Companies of all sizes will begin using these devices as costs go down and they become more accessible. The change is that these digital twins will become a commodity rather than bespoke machinery.

- AI and Machine Learning Integration

The next evolution of digital twins will be tied to AI and machine learning engines, enabling even more intelligent decision-making. These integrative, self-learning, digital twin predictive maintenance, and automated-response-capable systems will follow. This will, in the long run, allow businesses to shift from reactive tactics to proactive ones.

- Smarter Cities and Infrastructure

As cities expand, digital twins will be employed to design more intelligent infrastructure, to control utilities, and to manage transportation networks.

Government bodies can use those replicas to anticipate urban problems and respond more quickly. Eventually, a digital twin will serve as the underpinnings for tomorrow’s smart cities.

Conclusion

From a simple definition of digital twin along with some complex, real-world applications, the tech has graduated from industry buzzword to business necessity. IoT, AI, and the cloud connect digital twins to the physical world.

The path begins by understanding what a digital twin is, followed by smaller-scale tests, and culminates in digital twin initiatives being implemented across an enterprise.

Whether it’s predicting when a jet engine will fail, designing a more efficient electric car, or building intelligent grid networks in a city, digital twin technology is transforming industry at a remarkable rate.

For startups or enterprises of all sizes, the question is no longer what a digital twin is but instead how soon you can get it up and running to remain in the game. At Codeflash Infotech, we help businesses adopt and scale digital twin solutions to stay ahead in this rapidly evolving landscape.

Frequently Asked Questions

System, process, component, and asset twins predominate. Each serves a different level of detail, from single parts to entire workflows.

No, IoT collects and transmits data, but a digital twin uses that data to build a virtual model for analysis, forecasting, and optimisation.

Digital twin market leaders include Siemens Teamcenter, GE Predix, PTC ThingWorx, Microsoft Azure Digital Twins, and IBM Digital Twin Exchange.

The answer is no, because digital twin cloud computing offers an alternative approach to bridging the digital divide between medium and small-sized enterprises (SMEs, startups, etc.) and NPEEs. This approach enables them to scale down their learning processes, thereby enhancing their performance and usefulness.