What Is a Digital Twin? Definition, Types, and Uses

26 August

Introduction

Digital twin technology is transforming the landscape for corporations looking to gain a competitive advantage. The global digital twin sector is anticipated to achieve a valuation of $183 billion by the year 2031, as stated by Gartner.

This growth demonstrates how rapidly companies are implementing this technology to use real-time virtual representations of physical systems to improve decision-making, reduce downtime, and boost productivity.

Learning about digital twins can transform how you monitor assets, optimize systems, and create new products, whether you work for a large corporation, a manufacturing company, or a tech startup. Let’s take a look at what digital twin technology is and how it works. And why it’s important.

Digital Twin Concept/ what is a digital twin

Digital Twin model monitors and simulates physical asset performance, condition, and behaviour using digital and physical technologies.

These digital copies are produced by sensors integrated into physical assets. Online platforms receive real-time data from the sensors for analysis. The goal is to learn about the asset’s lifecycle from creation to upkeep.

Because they help businesses reduce costs and increase reliability, digital twins are a crucial component of asset life cycle management. In summary, there is most likely a digital counterpart to anything you can create in real life.

How does digital twin technology work?

IoT, machine learning, big data analytics, and 3D modelling are just a few of the cutting-edge technologies that are used in digital twins to create real-time simulations of actual events. The approach generally has these steps:

- Data collection: Sensors collect data, such as temperature, pressure, motion, and energy consumption, in real time from the physical system or object.

- Data Integration: One platform is used to process and synchronize the data with the digital twin.

- Visualization & Simulation: A digital copy is created and updated with data in real time using CAD (Computer-Aided Design) models or 3D scanning.

- Analysis & Insights: Algorithms model future events, predict potential issues, and devise solutions using the digital twin.

Businesses can conduct virtual tests, identify issues before they arise, and make data-driven decisions thanks to this real-time data synchronization. A fleet of trucks, a smart building, or a piece of manufacturing equipment can all be seen, analyzed, and performance improved with the use of digital twins.

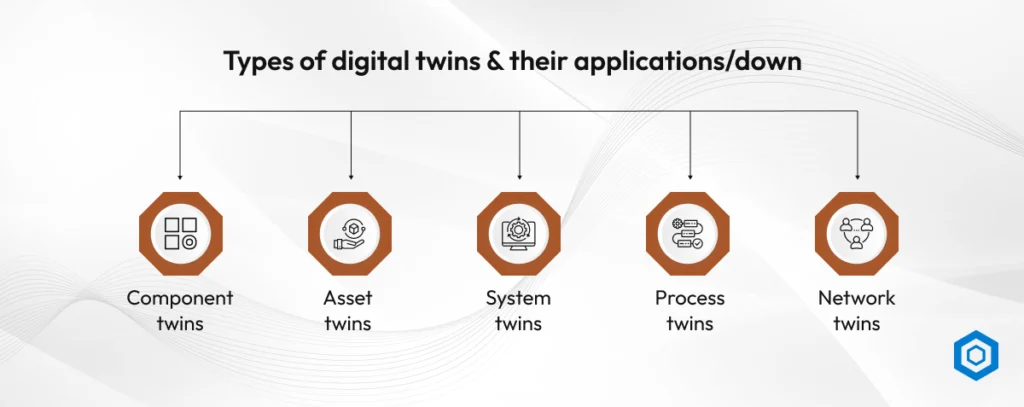

Types of digital twins and their applications/down

Digital twins can take many different forms, depending on their intended use. Each type of digital twin, from single components to entire systems, is meant to reflect varying levels of complexity and detail.

- Component Twins

The component twin is the easiest type of digital twin since it just models one aspect of a system. This is the most important aspect. They stand for distinct sections or pieces of a system or product.

These digital models help manufacturers monitor the performance, wear, and deterioration of small but critical components, enabling preventive maintenance and design improvements.

- Asset Twins

When you combine more than one component twin, you get an asset twin. They illustrate the interconnection between various sections of a machine or other equipment. Asset twins help you find problems with the whole system and try out upgrades or changes without affecting how things work in the real world.

- System Twins

You can use system twins to model whole systems, such as production lines or networks of cars. They help you see how machines or processes work together in real time better. System twins are essential for making an ecosystem work better, making workflows more efficient, and using less energy.

- Process Twins

Making Twins Process twins are exact copies of workflows or processes, like supply chains or manufacturing cycles. These twins are very useful for finding problems and delays. Businesses use process twins to help departments work together better, cut down on downtime, and get more done.

- Network Twins

Network twins monitor numerous interconnected systems, often located across the globe. They let businesses run and watch big operations in a virtual world. These are very helpful in areas like smart cities, telecommunications, and international logistics.

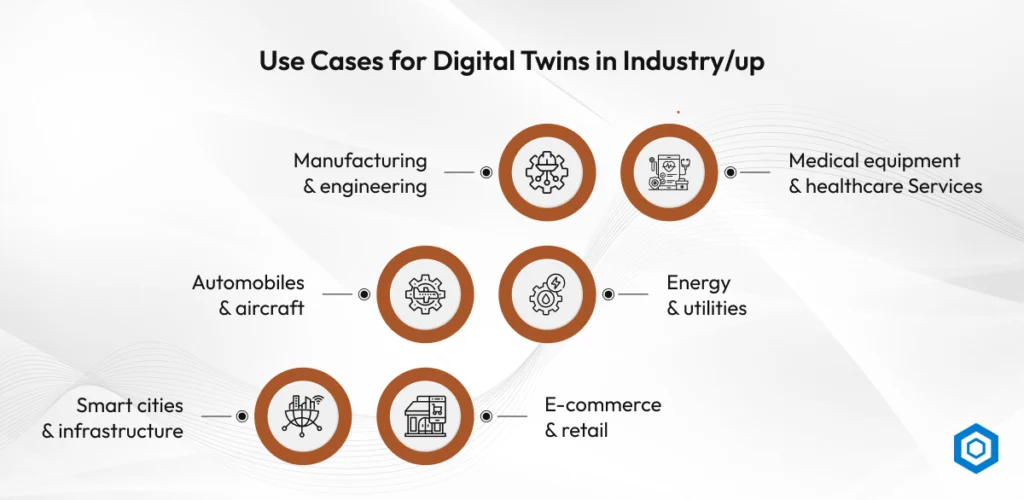

Use Cases for Digital Twins in Industry/up

Many businesses use digital twin technology. Digital twins are changing the way businesses make data-driven decisions by making operations more efficient and allowing for predictive maintenance.

- Manufacturing and Engineering

Digital twins in manufacturing improve production lines by showing changes in performance and process in real time. Engineers can save time and money by testing different setups on a computer before making changes to the real world. Predictive analytics also helps reduce the duration of equipment downtime.

- Medical Equipment and Healthcare Services

Digital copies of organs or whole physiological systems are transforming diagnostics and individualized treatment regimens. For instance, we can use digital twins to model a patient’s reaction to a novel medication. Medical device manufacturers also utilize this technology to maintain and continuously monitor complex machinery.

- Automobiles and aircraft

Car and aeroplane makers use digital twins to monitor the condition of their vehicles and planes in real time. Because of these twins, they are able to identify potential defects before they become significant issues. They also experiment with new designs, enhance safety features, and extend the lifespan of products.

- Energy and Utilities

The utility and energy industries use digital twins to monitor and manage infrastructure such as power grids, wind turbines, and pipelines. These models help with following the rules, getting the most out of energy production, and predicting when a system will fail. Another job of the technology is to make it easier to use renewable energy sources together.

- Smart Cities and Infrastructure

Planners and governments use digital twins to plan, monitor, and maintain urban infrastructure. Medical device makers also utilize this technology to monitor and maintain complex equipment continuously.

- E-commerce and retail

Digital twins help retailers manage inventories and personalize customer experiences. A store’s digital twin can show how customers move around and help you find the best places to put products. It also makes it easier to see how well the supply chain and logistics are working in real time.

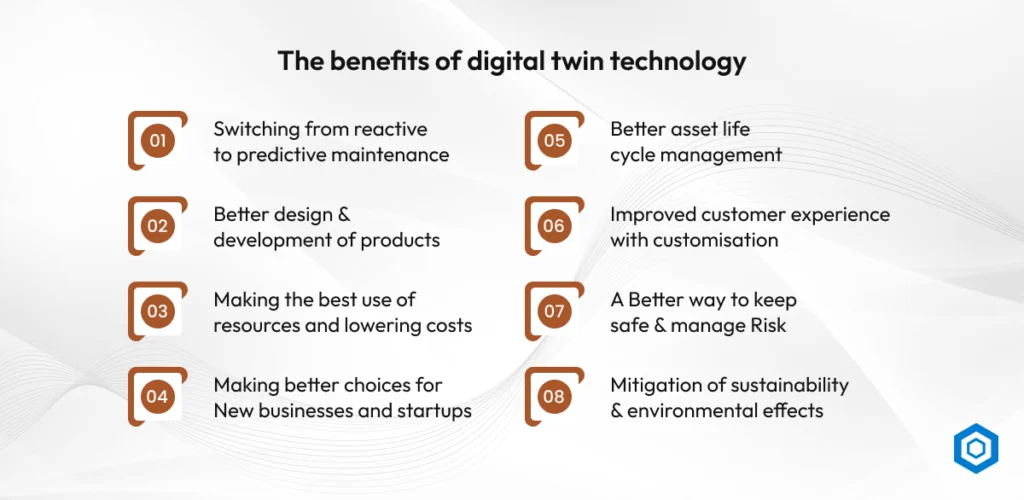

The benefits of digital twin technology

Digital twin technology is a powerful mix of real-time monitoring, simulation, and visualization. It gives companies the tools they need to make smart choices, work more efficiently, and cut down on downtime. Let’s examine a few of the most advantageous aspects.

- Switching from reactive to predictive maintenance

Digital twin systems are revolutionizing maintenance by providing real-time information on asset performance. Businesses can prolong the life of their assets, prevent disruptions, and maximize their maintenance budgets by implementing this change.

- Better design and development of products

Engineers and designers can use virtual models to see how a product will work in different situations. This iterative process finds problems, improves performance, and cuts down on the need for physical prototypes, which saves time and money.

- Making the best use of resources and lowering costs

Businesses can use digital twins to find problems with their operations and supply chains that slow them down. This visibility leads to better energy use, lower operating costs, and better resource allocation over the life of the asset.

- Making Better Choices for New Businesses and Startups.

Leaders can make better decisions by looking at real-time data and creating models of different situations. This will be very helpful for new businesses with little money and businesses that run big systems.

- Better Asset lifecycle management.

Digital twins simplify the process of monitoring every stage of an asset’s life, from installation to decommissioning. This makes it easier for asset managers to plan maintenance, use assets more efficiently, and make equipment last longer.

- Improved Customer Experience with Customization

Industries including manufacturing, retail, and automotive can offer customized products through the use of digital twin-driven simulations. As a result, customers are happier, and production can keep going.

- A Better Way to Keep Safe and Manage Risk

Digital copies help companies predict and prepare for future events. This kind of foresight helps reduce risk and improve safety plans, which is a benefit that many industries, including oil and gas, construction, and aviation, have adopted.

- Mitigation of Sustainability and Environmental Effects

With the aid of digital twins, companies can test energy-saving strategies and reduce emissions in virtual environments. This encourages compliance with environmental regulations and corporate sustainability goals.

Future Directions for Digital Twins

As digital twin technology advances, it is integrating with other powerful innovations such as artificial intelligence, the Internet of Things, and analytics to unleash new potential. In the future, digital twins will be employed for real-time prediction, optimization, and innovation in addition to the digital replication of physical objects. What’s ahead:

- Integration of artificial intelligence (AI)

Going beyond simple monitoring, AI-powered digital twins will be able to learn, adapt, and self-optimize based on both historical and current data. Twins will be able to anticipate issues, offer solutions, and develop with minimal assistance from humans thanks to AI algorithms. As a result, industry systems become more intelligent and self-sufficient.

- Using Predictive Analytics to Improve Operations

Businesses will be better able to forecast the future with the use of digital twins and predictive analytics. Planning, resource management, and risk mitigation all improve as a result. Data-driven foresight and proactive decision-making will be advantageous for sectors like energy, healthcare, and logistics.

- Digital twins of infrastructure and cities

Digital twins will revolutionise city planning and construction. Governments and planners can create smarter, safer, and more sustainable cities by testing energy grids, traffic patterns, and emergency responses using a virtual model of physical objects. It also facilitates improved stakeholder communication.

- Enhanced Cybersecurity in Twin Architectures

The increasing integration of digital twins into mission-critical systems will lead to a significant trend in cybersecurity. Advanced security layers and encrypted data transfers will become essential to safeguard digital twins against cyberattacks and to guarantee data integrity and safety.

- Expanded Function in Climate and Sustainability Modelling

Climate patterns, water consumption, and carbon emissions are being modelled using environmental digital twins. This promotes ESG reporting and sustainability projects. Through virtual experimentation, governments and businesses can make well-informed, environmentally responsible decisions.

- The Development of Tailored Healthcare and Medicine

Medical professionals will be able to model treatments and forecast health outcomes by using digital twins of human organs or entire physiological systems. As a result, new drug development will proceed more quickly, and personalized medicine will transform patient care.

Conclusion

Digital twin technology is changing entire industries by establishing a connection between the digital and physical worlds. Whether a company is optimizing supply chains or a startup is validating product concepts, digital twins help lower risks, save costs, and speed up innovation.

The combination of AI, IoT, and sustainability-driven analytics ensures a bright and scalable future for this technology.

Codeflash Infotech can help you begin implementing business-specific digital twin solutions by providing end-to-end development support. Check out our IoT app development experience to start your path to a smart, connected future.

Frequently Asked Questions

Model, monitor, and improve performance with a digital twin, a virtual representation of an asset or process updated with real-world data.

Numerous industries, including manufacturing, healthcare, automotive, energy, retail, and smart cities, can benefit from the operational insights and performance improvements that digital twins offer.

Indeed, startups can use digital twins for rapid prototyping, system simulation, and product testing to cut costs and speed up development.

AI adds intelligence for automation and analysis, enhancing the precision and responsiveness of digital twins, while IoT provides real-time sensor data.