The Role of Software Development in Manufacturing: An Overview

29 NOVEMBER

Many firms grapple with the challenge of reducing expenses while enhancing productivity and efficiency, particularly in the manufacturing industry. According to a recent PwC survey, over 42% of respondents consider supply chain disruption a significant risk, as it can lead to production delays and impact output.

Thankfully, technological advancements have provided Software Development in Manufacturing solutions to help companies achieve their specific objectives. Today, manufacturers leverage custom-built software to align with their unique business goals and operational demands.

This shift has driven SMEs and large corporations to embrace Software Development in Manufacturing. Creating effective software for production requires a user-centric design, a robust tech stack, a commitment to security and compliance, and a deep understanding of industry trends.

If you’re considering Software Development in Manufacturing for your production needs, you’re in the right place. Here, we’ll explore the essential components of manufacturing software, including its features and benefits.

What is Manufacturing Software?

Manufacturing software is a group of tools and systems developed significantly to help manufacturers manage their supply chains, production processes, and operational workflows.

These software programs facilitate data collecting, automation, and real-time monitoring, which enhances operational effectiveness and decision-making. Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), and Product Lifecycle Management (PLM) software are typical examples.

Businesses may optimize resources and cut costs by using manufacturing software, which offers real-time insights into every stage of the production cycle, from procuring raw materials to distributing finished goods.

How Can Businesses Benefit from Manufacturing Software Solutions?

Businesses can benefit from manufacturing software in many ways, as it increases productivity and fosters technological expansion. Here are a few significant methods it can assist:

- Improve the caliber of the product

Software Development in Manufacturing helps companies improve their products by tracking each step of production and seeing possible problems before they become serious. Real-time data collecting and analysis enables companies to:

- Keep up stringent quality control procedures.

- Early defect detection keeps flaws from getting to customers

- Processes should be optimized for constant product quality.

To ensure that products meet client expectations, the software frequently incorporates quality management tools that monitor production parameters, assess performance, and offer insights for ongoing improvement.

- Quicken the Production Process

The potential of software development in manufacturing to speed up the production process is one of its most significant benefits. Companies can utilize automation and real-time tracking to:

Reduce bottlenecks and streamline processes.

- Simplify processes and reduce bottlenecks.

- Make labor management and resource allocation as efficient as possible.

- Boost the precision of production forecasts and scheduling.

- Faster delivery times, higher production, and eventually higher customer satisfaction result.

- Minimize Unplanned Downtime

Manufacturers may have to pay for unscheduled downtime. Manufacturing software solutions that offer predictive maintenance capabilities help avoid these interruptions.

Recognize wear and tear early on.

- To prevent malfunctions, plan maintenance in advance.

- Send out notifications when equipment maintenance is necessary.

- Cut down on expensive manufacturing stops.

- Businesses may guarantee uninterrupted operations and increase profits by reducing unscheduled downtime.

- Boost Inventory Control

For every industrial organization to succeed, effective inventory management is essential. Manufacturing software provides information on supply chain logistics, production needs, and stock levels, helping inventory optimization. Benefits consist of:

- You are tracking and monitoring inventories in real-time.

- Raw material reordering is automated and dependent on demand projections.

- I am cutting back on surplus inventory and related holding expenses.

- Enhanced knowledge of supplier performance and lead times.

- Enhancing inventory management can help companies cut expenses, prevent stockouts, and keep production flows more efficient.

Detailed Procedure for Developing Manufacturing Software

It’s time to start developing your manufacturing software when you’ve decided which features to include. However, it’s crucial to comprehend customer needs, consider market demands, select the best development strategy, etc., before proceeding with the development process.

- Establish Your Vision

The first stage in developing a manufacturing software system is establishing your goals and comprehending the type of software your company requires, the features you want to incorporate, and other factors. It is easy to proceed when you have carefully reviewed your needs and plan. - Make a layout

Your design should outline the software’s appearance and feel, the structure and storage of data, and the interactions between the various modules. - Choose the Proper Tech Stack

It’s crucial to pick the technology that will work best for your project. The next phase proceeds smoothly if you choose the best tech stack for your manufacturing software. - Hire Professionals

The moment has come to seek seasoned professionals with solid software development aptitude. For this reason, you need to recruit skilled software developers who can work on your project with passion and deliver excellent results. - Develop Software

The most crucial phase is building integrated industrial software systems with rich features, current development trends, and a modern tech stack. The professionals you work with will make this task more accessible and efficient. - Software Testing and Launch

You should test your development after it is finished. You are prepared to go live if your software is error-free and functioning as intended.

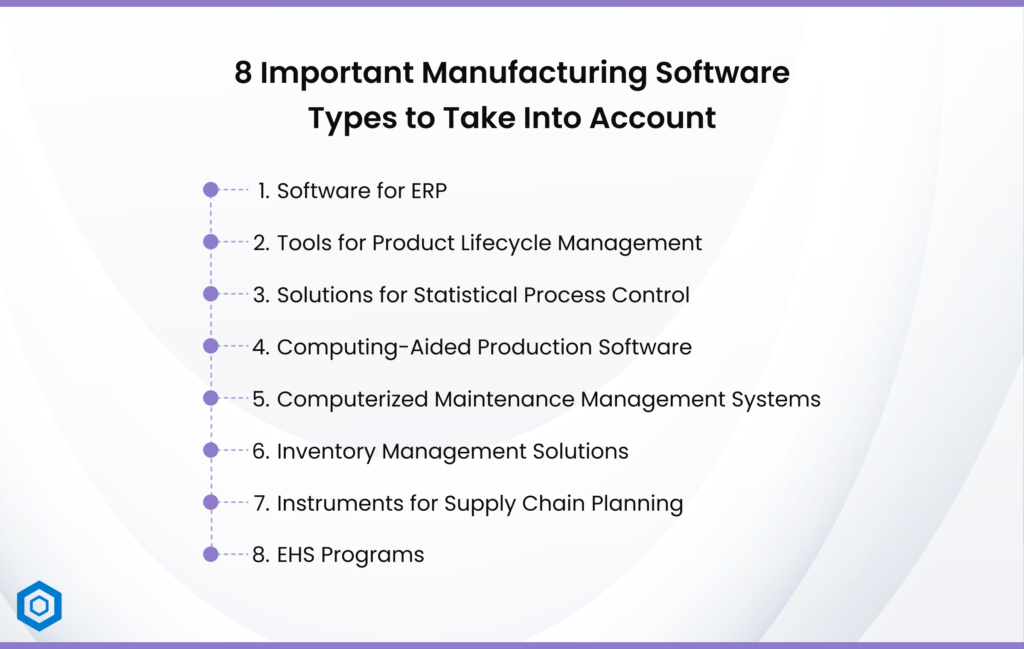

8 Important Manufacturing Software Types to Take Into Account

- Software for ERP

ERP systems are undoubtedly one of industrial enterprises’ most widely used software types. These technologies help with project management, accounting, procurement, production, supply chain monitoring, compliance, and other day-to-day corporate activities.

An ERP system for manufacturing usually reduces costs and enhances organizational effectiveness through optimal utilization of company resources. The technology’s ability to provide insight across numerous manufacturing areas and administration from a central platform makes this possible.

The conclusion that ERP software is critical to the industrial sector is logical. Because it helps in managing numerous facets of the corporation, it might be a lifeline for multiple companies. - Tools for Product Lifecycle Management

An application that manages the product life cycle (PLM) can benefit manufacturers, especially those who wish to manage product data effectively.

These solutions are one-stop shops for all information about engineering change orders, production records, item components, initial product specifications, quality protocols, and related subjects.

Therefore, there is no need to search further to gain a comprehensive perspective on product creation. A well-designed PLM system will enable you to increase production rapidly and guarantee that your products are consistent with the highest caliber. - Solutions for Statistical Process Control

A poor product is one of the worst things a manufacturer can do to their business. It frequently happens due to accidents that occur during the production process. Some software for statistical process control (SPC) is used to avoid issues.

For real-time quality control, it employs industry-standard methods throughout the manufacturing process. In essence, SPC examines data from various metrics relating to the product and the process to see whether any unacceptable variances that require correction exist.

Productivity is increased, quality is enhanced, and expenses associated with handling faulty items are decreased using SPC software. - Computing-Aided Production Software

Computer-aided manufacturing (CAM) software technologies build data machines that can be used to create finished products using computer-aided designs that specify dimensions or types of materials.

Overall, CAM software enables you to create products straight from a design rather than physically assembling and running gear. As you might expect, production managers and shop floor workers who are willing to adopt time-saving and error-reducing solutions are the ones who usually use them. - Computerized Maintenance Management Systems

Maintenance solutions are crucial manufacturing control software. After all, no one likes to deal with degraded assets that hinder productive output. Therefore, some businesses have resorted to computerized maintenance management systems (CMMS) that are comparable to the previously discussed EAM software type.

Although they have similar features, CMMS primarily focuses on maintenance rather than asset management across various business processes.

Thus, a CMMS makes it easier to keep equipment in good condition by centralizing information related to maintenance. This program can help maximize the utilization of equipment, trucks, plant infrastructures, and other resources. Consequently, costs are reduced, and efficiency is increased. - Inventory Management Solutions

Any company that sells things must manage inventories well. Thus, manufacturers buy inventory management software frequently.

These technologies automate stock tracking, product reordering, and warehouse management while providing real-time inventory data. This reduces out-of-stock and overproduction, increasing profitability. - Instruments for Supply Chain Planning

Supply chain planning tools surpass conventional inventory management solutions regarding logistics and stock-level coordination. This manufacturing software covers almost every aspect of delivering items to customers.

They help identify supply chain problems and offer solutions to prevent them, even with minor damage. Additionally, these methods can forecast supply and demand to enhance delivery and plan schedules.

A well-designed supply chain monitoring program will allow you to observe how your shipment is handled from start to finish and find ways to optimize the efficiency of the entire production process.

If you want to dive deeper into Supply Chain Management, check out our comprehensive Supply Chain Management Software Guide! - EHS Programs

The manufacturing industry must adhere to regulations. Numerous requirements must be met, whether ensuring workers’ safety and well-being or tracking manufacturing’s environmental impact. Ecological health and safety (EHS) software could be helpful in this case.

What exactly is EHS software, then? EHS solutions are the primary data sources for sustainability, occupational health and safety, and waste output analysis and storage. They support manufacturers in conducting inspections, monitoring pertinent environmental metrics, and monitoring dangerous items.

Your company may reduce waste generation, minimize workplace dangers, and comply with all applicable regulations by implementing EHS management software.

Software for Manufacturing Management's Future

Software development services for manufacturing are crucial for encouraging productivity and creativity in the business world. By utilizing state-of-the-art technologies and following best practices in software engineering, manufacturers can obtain a substantial competitive edge in today’s ever-changing market.

Incorporating innovative manufacturing software solutions will become increasingly essential for success as we proceed toward Industry 4.0 and beyond. Manufacturing experts and software developers must stay on top of emerging trends and continuously enhance their processes in this rapidly evolving business.

If your business needs cutting-edge production management software, a personalized ERP solution, or distinctive manufacturing execution system software, contact Codeflash Infotech‘s solutions professionals. Unique software solutions that enhance your life and grow your manufacturing business are what we design and develop. Get in touch with us now!

Conclusion

Developing custom software is essential for manufacturing business owners to remain competitive in a technologically advanced world. You may design customized software development solutions that optimize workflows, cut expenses, and enhance product quality by being aware of the custom software development process and working with an established software development company such as Codeflash Infotech.

Custom manufacturing software is more than an operating tool; it’s a wise investment supporting long-term growth, business scaling, and market adaptation. The correct software development solutions will enable your company to succeed, whether your goal is to automate your production line, enhance data-driven decision-making, or optimize inventory management.